The world's longest "quickie" refurb?I bought this Rado Diastar 10 Diamaster about two and a half years ago.I bought this Rado Diastar 10 Diamaster about a year and a half ago. Rado made 2000 of these between 1968 and 1972. They came with a white, black or blue dial. They are extremely hard to find and are some of the highest priced vintage Rados of all. I bought this one off ebay for about 5% of the highest price I have seen one go for.

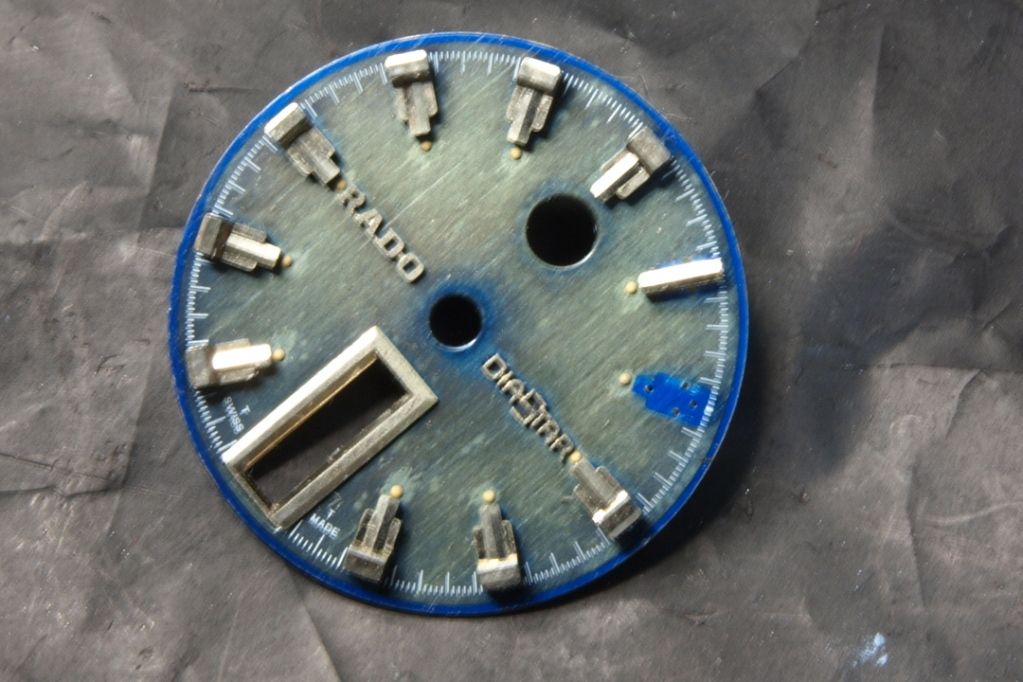

The lightweight fishtail is in terrible condition and the watch itself is covered in decades of grime. TC can sometimes stain from this much garbage. The day wheel is lazy and doesn't actually display the day properly. The dial looks like faded black but is actually the transparent blue variety. It once looked like this:

I managed to acquire a NOS Diamaster dial which cost roughly as much as I paid for the watch. I did a swap about 8 months ago. I can't remember where I put the old dial but it came out looking similar to this Disatar 14 dial:

No problem. A quickie job.

During the swap I discovered that the day wheel was acting like it was because the dial spacer was missing and the entire surface of the day disc was covered in oil. I cleaned the disc and assembled the watch. I wore it once or twice but had not rebrushed the bracelet and had not put a new dial spacer in. I took it apart and then... left it. I finally got back to after about eight months or more.

The AS 1876 with push button date advance:

PA110279 by hankblanc, on Flickr

This movement was used by Rado in the Diamaster and in the Diastar 8. It is notoriously finicky and is the only automatic movement Rado ever used that had an unsigned rotor.

P1012852_01 by hankblanc, on Flickr

I did not touch the caseback. It has never been polished and shows only moderate signs of wear. A clean with lemon juice and sea salt is all it got. Rebrushing fishtails or cuff style bracelets can be tricky. Each link is curved and if one wants a nice consistent result across the entire bracelet it must be brushed while assembled and curved. I do one side at a time. I use double sided tape to fix the bracelet to an 8 oz. jar of Golden acrylics (this is roughly the right size curvature for an 8" bracelet). I fix a piece of sandpaper too a perfectly flat patch of my wokbench and then fix parallel guides that are the exact width of the jar on it's side. Finally I put the jar between the guides and roll it across the sandpaper. One cannot stop a rolling lotion until the entire bracelet is clear of the sandpaper. I start with something quite coarse, 320, to remove all the old brushing and to get a nice deep new brush. Then I will use an 800 and finally 1500 to remove the peaks from the new brush, leaving only a flat srface with valleys. This is the result on the lightweight fishtail from the first photo.

P1012848_01 by hankblanc, on Flickr

P1012846_01 by hankblanc, on Flickr

P1012845_01 by hankblanc, on Flickr

The tungsten case and the sapphire crystal both got a clean with a polishing compound and the case front is flawless. This is a bit unusual on a Diamaster. The flat surface on these monsters is huge and they often end up scuffed.

Thanks for looking.

Likes:

Likes:

Reply With Quote

Reply With Quote